|

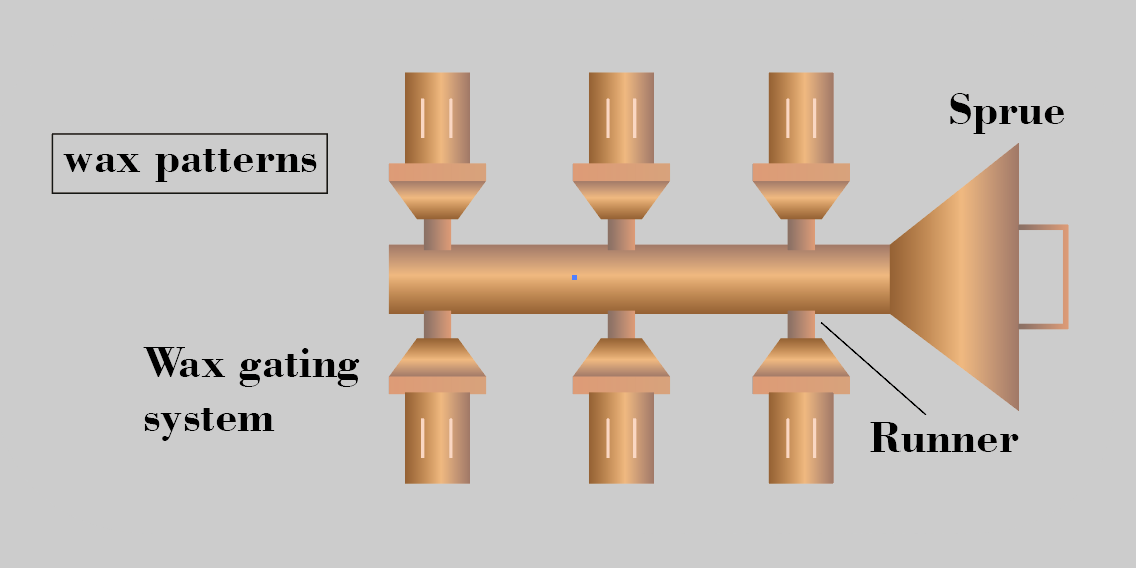

Wax patterns

The first step in the die casting process is to make a mold. The mold is usually made of steel or aluminum and is designed to withstand the high temperatures and pressures of the die casting process. |

|

|

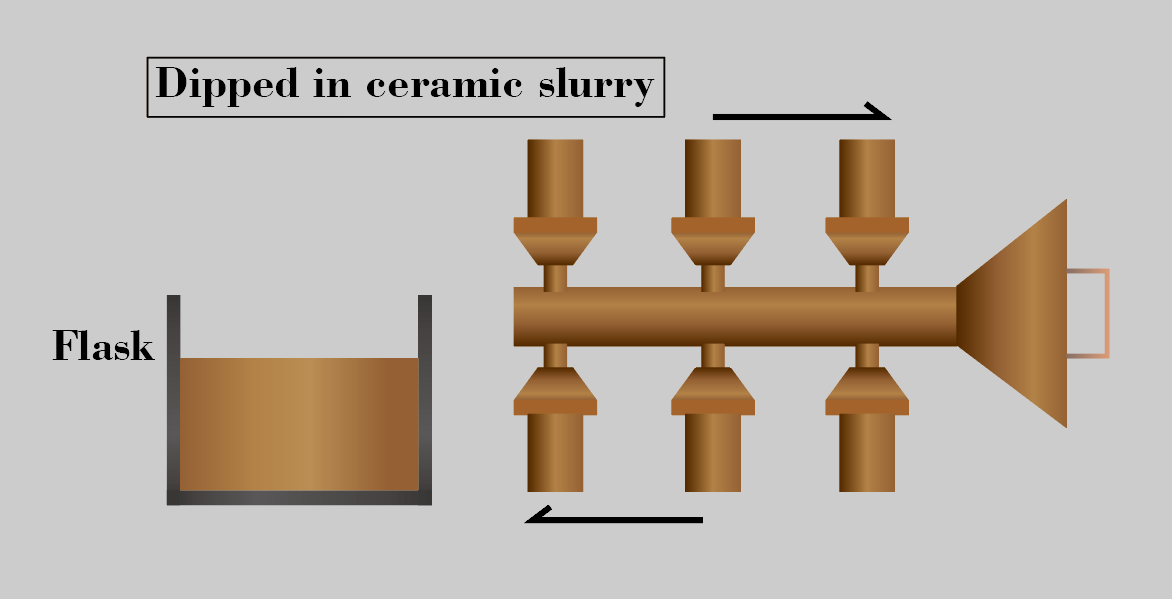

Dipped in ceramic slurry

When the metal is liquid, it is injected into the mold under high pressure. Molten metal fills the mold cavity and cools to form the desired shape |

|

|

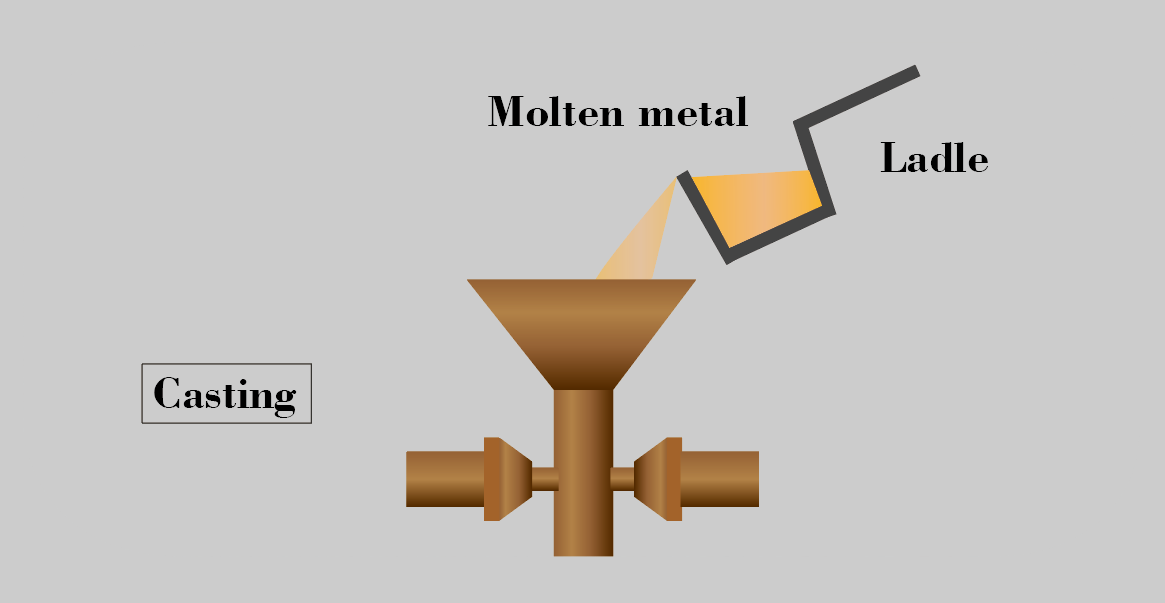

Casting

Once the metal has cooled and hardened, open the mold and remove the parts. Ensure that the parts are completely cooled before handling to avoid any potential injury |

|

|

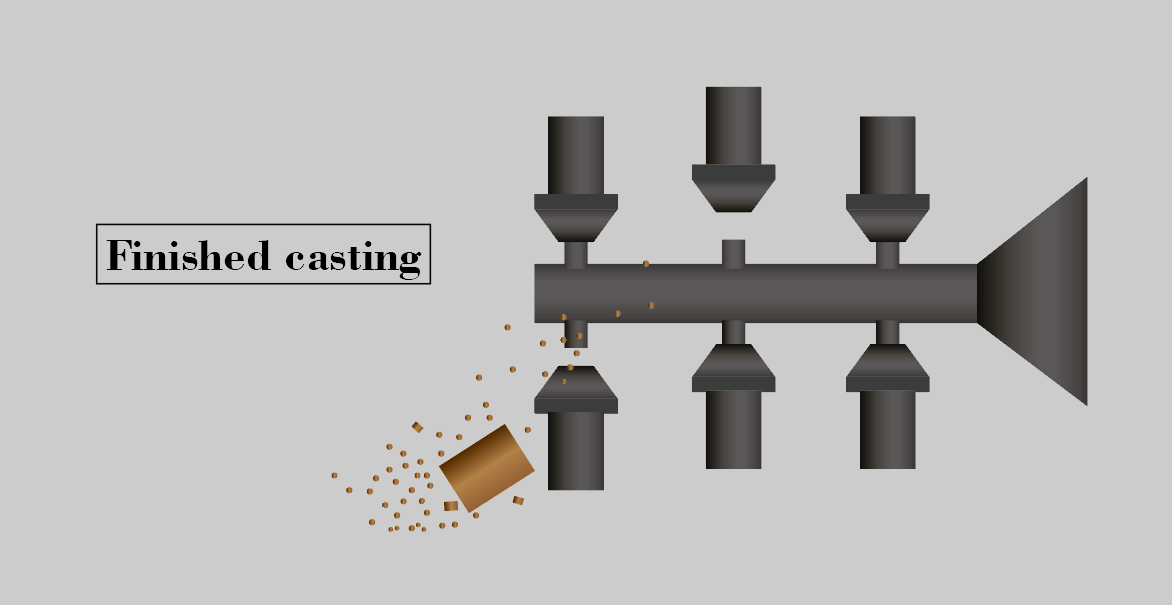

Finished casting

The final step in the process is to finish the part. Surface finishing plays a crucial role in die casting because it affects the durability and function of the part. Standard finishing processes include anodizing, powder spraying, wet plating, etc. |

|